In the history of Taiwan’s tea industry, no place has shaped its destiny as profoundly as Lu Gu Township. Through what seems like a simple competition system, Lu Gu not only created the unique concept of “Competition Tea,” but also established a benchmark of quality standards that continues to guide Taiwan’s tea production today.

When you step into a tea shop and hear the owner proudly say, “This is competition-grade tea,” have you ever wondered where that standard comes from? Why could a small township like Lu Gu set rules that impact the entire Taiwanese tea industry? The answer lies in a nearly fifty-year-old system that continues to evolve and refine itself.

From government promotion to nationwide passion, from 104 submitted tea samples to an astonishing 4,048 entries, how did Lu Gu rewrite Taiwan’s tea history through one competition system?

Government Promotion: From Tea Drinking Habits to Industrial Policy

In 1976, when the Provincial Department of Agriculture and Forestry decided to “guide the Lu Gu Farmers’ Association in holding the first Spring Tea competition,” the intention was simple: to encourage Taiwanese people to drink more tea. At that time, Taiwan’s booming economy needed cultural anchors, and the government aimed to cultivate tea appreciation while helping farmers improve income.

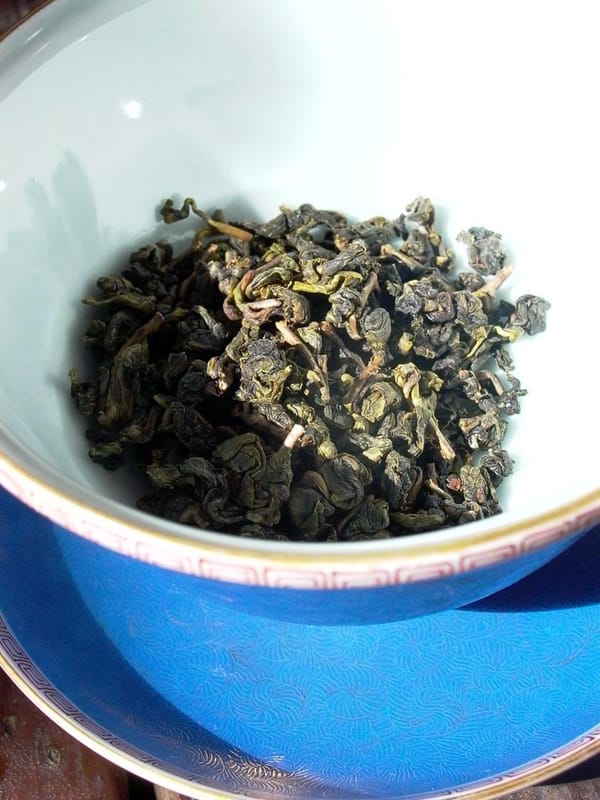

That first competition, held at Lu Gu Elementary School, featured only 104 tea entries. Yet, it carried massive potential. Lu Gu was chosen not by chance: it boasted exceptional conditions—elevations ranging from 200 to 2,025 meters, an average temperature of 25°C, rainfall between 2,000–2,300 mm, and the historic 1885 introduction of Soft-stem Oolong by Lin Fengchi from Fujian (a milestone in Taiwan’s Oolong history).

Most importantly, almost every household in Lu Gu produced tea, providing fertile ground for such a system. The farmers’ pursuit of quality aligned perfectly with government policy, creating a seamless synergy.

The Smart Price Mechanism: From Guaranteed Buyouts to Market Pricing

The success of Lu Gu’s competition system largely came from its pricing strategy. In 1978, the Farmers’ Association guaranteed to buy First Prize tea at NT$1,800 per jin (600 g)—an exceptionally high price at the time—plus a cash reward of NT$20,000.

Adding to this was an ingenious tactic: consumers could only buy up to two jin each, with additional sales decided by lottery. This scarcity-driven approach boosted prestige and consumer trust.

In 1979, a key shift occurred: “Competition results allowed farmers to bargain directly with consumers, while the association only charged entry fees.” This marked the transition from government-led promotion to a market-driven system. Tea prices were now shaped by supply and demand, motivating farmers to pursue excellence.

By 1980, the system evolved further: “All qualified entries were purchased at NT$700 per jin for promotional use,” later adjusted to NT$1,500 today. This balance secured farmer income while maintaining competitiveness.

Professionalizing the Judging System: From Authority to Local Talent

The legitimacy of competition tea depended on professional judging. Early competitions relied on experts from Tea Research Stations as head judges, ensuring scientific rigor and consistency.

However, by the 1991 winter competition—with a staggering 4,048 entries—the system faced manpower shortages. The solution? 24 local young farmers were selected and rigorously trained as judges.

This local training had multiple benefits: solving labor issues, cultivating professional expertise within the community, and grounding evaluation standards in Lu Gu’s tea traditions.

Scientific Evaluation: Standardized Methods for Quality Assurance

Another innovation was the standardized tasting protocol:

- 3 grams of tea measured precisely

- Brewed in 150 c.c. cups

- Steeped in 100°C water for 6 minutes

Judges then assessed systematically: observe liquor color, smell the leaves at around 40°C, and finally taste the tea.

Evaluation criteria were comprehensive: appearance (shape, color), liquor (color, aroma, taste), and leaf base. This multi-layered system balanced both external and intrinsic quality.

Fairness Through Two-Stage Judging

With large-scale entries, Lu Gu adopted a two-stage judging system. Local judges first categorized teas into elimination, second-flower, third-flower, and semi-finalist categories. Roughly 25% advanced to the semi-finals.

Professional head judges then determined Third, Second, First, and Special Grade winners. Only about 16% achieved award-winning status, ensuring both inclusivity and prestige.

Packaging Innovation Driven by Competition Tea

Competition standards didn’t just refine quality—they pushed packaging innovation. Milestones included:

- 1985: Aluminum foil packaging

- 1990: Oxygen absorbers

- 1997: Vacuum nitrogen packaging

These ensured freshness and quality preservation, influencing Taiwan’s entire tea industry.

A New Benchmark: From Lu Gu to All Taiwan

The strict standards of competition tea reshaped Taiwan’s tea industry. Teas not meeting benchmarks were eliminated outright, ensuring only excellence prevailed.

Thus, “Competition Tea Grade” became synonymous with quality assurance, extending beyond Lu Gu into Taiwan’s shared industry language.

Industry Clustering: From Individual Competition to Collective Prosperity

Beyond individual gains, the system fostered a cluster effect:

- Farmers directly engaged with consumers

- Higher prices rewarded quality

- Nearly every family in Lu Gu produced tea

This healthy competition pushed farmers to refine techniques, elevating the entire region’s expertise and cementing Lu Gu as Taiwan’s Tea Village.

Conclusion: A Model of Institutional Innovation

Lu Gu’s Dong Ding Oolong competition system demonstrates how a well-designed framework can:

- Raise product quality

- Establish brand prestige

- Drive technological advancement

- Create sustainable industry development

From 104 entries in 1976 to over 4,000 by 1991, the system reshaped Taiwan’s tea landscape.

Each sip of Dong Ding Oolong today embodies not just craftsmanship, but the brilliance of institutional design. Lu Gu’s journey proves: with the right system, even a small township can set industry-wide standards, turning a cup of tea into a vessel of pride and dreams.